FAQ’s

What are duplex strainers, and how do duplex strainers work?

Duplex strainers are two filters/strainers in one system so you can keep flow moving while one side is cleaned and the other stays online. Saniclean’s duplex arrangements are designed specifically to support continuous operation.

When should I choose duplex strainers instead of a simplex strainer?

Choose duplex strainers when your process can’t afford shutdowns for cleaning or maintenance—especially in continuous production environments. They’re built to help you switch flow and keep production running with less downtime.

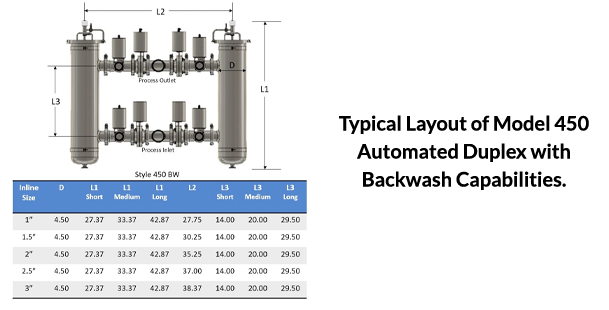

Do duplex strainers have backwash capability?

Saniclean’s duplex strainers can be configured with backwash capabilities in either manual or automated setups. In automated configurations, switching and/or backwash can be triggered according to predetermined pressure differentials.

How do I size/spec duplex strainers (micron rating, pressure, viscosity, flow)?

To spec duplex strainers, you’ll typically provide flow rate, fluid type/viscosity, target retention (microns), and operating pressure so the correct configuration and element can be selected. Saniclean notes filtration options like wire mesh, perforated, and wedge wire elements (with retentions down to 5 microns) and also designs specialty strainers for higher pressures and viscous service.