One major advantage of the “RS” strainer is that it can be installed horizontally or vertically and cleaned without having to disassemble process piping.

As experienced “RS” and “L” strainer manufacturers, SaniClean Strainers offers a complete line of strainers designed to meet your manufacturing or processing needs. Among the features and options are:

- O-ring seals for optimal performance

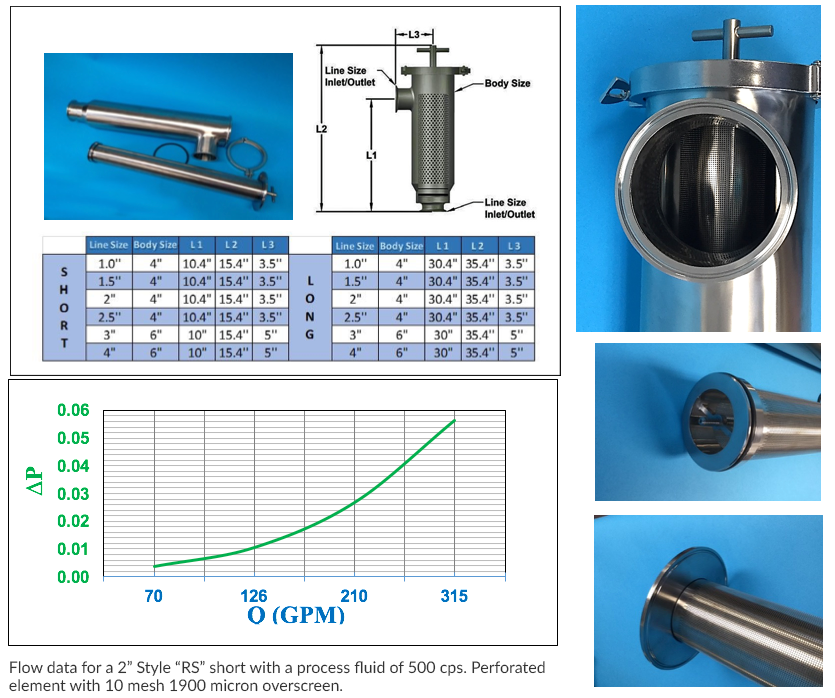

- 1” to 4” line sizes in short and long capacities.

- Connections: Clamped (standard), I-Line, Bevel Seat, Butt Weld

- Surface Finish: 25 Ra Internal, 35 Ra External

- Perforated Back-Up Tube: with 1/8-inch or 1/4-inch diameter holes

- Wire Mesh OverScreens with 12-200 mesh stock

- SANIWEDGE Wedge Wire Elementoffering slot openings to 50 microns

- SKS OverScreen which acts like wire mesh, but without any wire intersections

Filter Socks ranging from 1000 to 25 micro