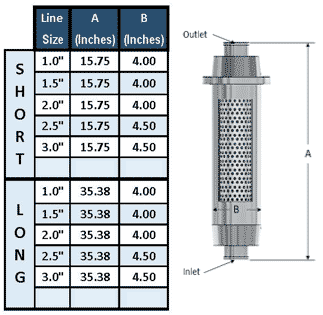

SaniClean Sanitary Inline Strainers, available from stock, provide ideal, cost-effective filtration. Crevice free and polished to 3A standards, SaniClean Strainers offer maximum flexibility accepting Wire Mesh and SKS Overscreens as well as high-quality Wedge Wire and disposable Filter Socks.

Contact our top team today by filling out our form below and we will get back to you on how we can best suit your needs.