When it comes to utilizing a straining method in your factory, perforated backup tubes should be among the first products you consider investing in in order to maintain the quality and integrity of your products. Because they work in a large variety of industrial applications, they are among the most important wire cloth products you could have at your facility. In this guide, we are going to go over what perforated backup tubes are, why they are so important, as well as addressing some previous misconceptions you may have had about perforated backup tubes.

What Is A Perforated Backup Tube?

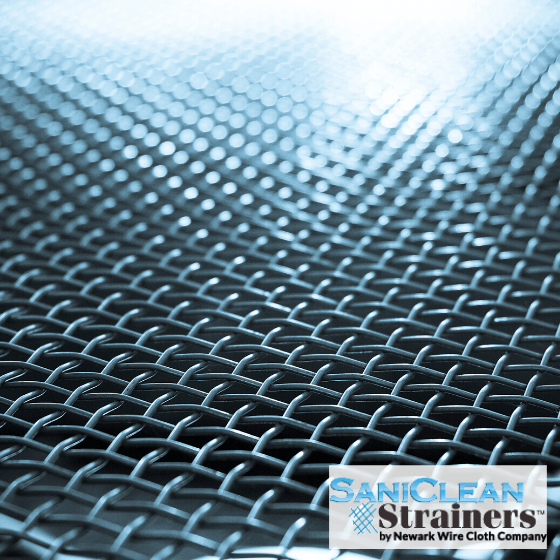

Perforated backup tubes are made up of 316L SS perforated sheets and rolled up via a mandrel into perforated stainless cylinders. The perforation in the sheets are punched with either 1/8″ or 1/4” diameter holes and are used on either side depending on the consistency of the item being strained. A welded seam runs the length of the backup tube in order to connect it to the industrial product used for straining.

What Are They Used For?

If you were to take just one wire mesh sheet, it would obviously work like a sieve to catch and separate larger products from more aqueous substances. In the factory setting, rolling up this sheet into a perforated stainless cylinder and attaching it to a Y strainer pipe can work as a tool that mechanically separates unwanted solids from liquid, gas or steam lines. The number of holes a stainless cylinder has also plays an important role in the separation of the materials. Depending on the final product you are working to develop, you will want to use anything from a coarse strainer to a fine filtration unit.

Levels of Perforation and Straining Quality

Perforated backup tubes come in many varieties that fit the function of the form they have been developed in.

- Coarse Straining Tubes: These are mainly used for large particles and have perforation sizes of 1/8’’ in diameter and 1/4’’ in diameter. These are the standard sizes but can be manufactured according to your specifications. A coarse straining tube effectively uses the base layer of a perforated backup tube without any additional wiring.

- Medium Straining Tubes: An original perforated backup tube is used with the addition of a wire mesh overscreen that is 75-1095 microns and can be customized according to the end product you are looking to achieve. Filter socks that go over the perforated tube can also be used for an additional layer of filtration

- Fine Filtration Tubes: Similar to medium straining products, a filter sock in conjunction with a 40-micron wire mesh overscreen can deliver a retention product for extremely fine separation.

New developments to the straining practice are being made every day. For example, SKS Overscreens are new overscreen varieties that work like wire meshes but don’t have the same wire intersections. This can work for superfine particulate separation where the exact measurement of the substrate is necessary.

What Industries Use Perforated Backup Tubes?

Perforated backup tubes have been used in the food processing and consumer product manufacturing industry for well over a century now with several updates coming as a result of technological innovation and automation. While the original perforated sheets were crude and could only serve in a few industries, perforation techniques since the middle of the nineteenth century have advanced greatly and can now serve a number of product categories. Nowadays, everything from ice cream, salad dressing and cosmetics use any number of perforated tube combinations to develop their finished products at any stage of production from pharmaceutical packaging to meat and dairy processing.

Takeaways

Perforated backup tubes have been used in manufacturing and product development for ages now and are being continually improved upon every day. With new products and add ons like overscreens and filtration socks being developed, expect even more uses for perforated tubes to be used in manufacturing.

- Perforated backup tubes are available as Coarse Straining Tubes, Medium Straining Tubes and Fine Filtration Tubes.

- They can be used in a variety of industries from food to cosmetics.

If you are interested or have any other questions, contact us today. Saniclean Strainers looks forward to helping you find and develop a filtration solution for your products.