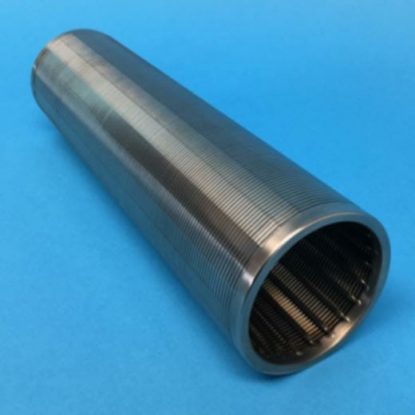

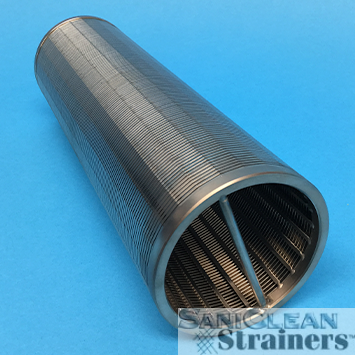

SaniClean’s Wedge Wire strainer element is an ideal solution for industrial filtration, separation or retention needs. This new solution replaces both the perforated support core/back-up tube and the wire mesh overscreen.

Industrial Wedge Wire Element Strainers

Our wedge wire elements are constructed from SAE 316L stainless steel. The elements use triangular-shaped wires that are continuously wrapped around the outside of internal support rods, forming a cylindrical strainer element. Wrapping is done with consistent spacing and slot openings between the wires, creating accurate spacing for the entire length of the element. All wire elements are made of SAE 316L stainless steel.

The SaniWedge wire strainer element is manufactured with precision, delivering consistent diameters and slot openings. The wedge wire elements are designed to be significantly more rugged, durable and long-lasting than wire mesh overscreens, SKS overscreens, or filter socks, able to withstand a 150-pound collapse pressure differential.

SaniWedge wedge wire is 3A-approved for dairy products if the slot opening is 0.005 inches or greater.

Wedge wire has many advantages if your manufacturing or processing business is using wire strainers, including:

- Minimal clogging

- Precise slot sizes to meet your production needs

- Surface filtration for simple cleaning using backflushing or scraping

- Self-supporting construction

SaniClean Strainers offers wedge wire elements in any slot-opening size you need. We offer a complete line of inline wire strainer products and side inlet strainers.

To learn more or request a quote on our SaniWedge strainer elements, contact us today.

Showing all 2 results