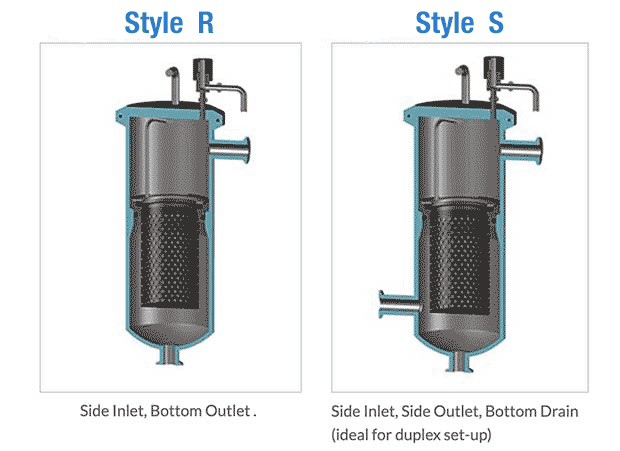

Newark Wire Cloth SaniClean Strainers represent a standard in Sanitary Basket Strainer industry. SaniClean Sanitary Basket strainers are a cost-effective solution for manufacturers and processors. They can be installed in vertical or horizontal pipelines and can be configured for duplex piping.

Interchangeability.

- No matter what kind of strainer basket used — perforated, perforated with a wire mesh liner, or wedge wire are designed to fit both.

Continuity.

- Strainer baskets can be removed, cleaned or replaced with breaking a piping connection. Changeover is fast and easy.

Flexibility.

- The SaniClean basket strainer can be piped in simplex or duplex.

Safety.

- All SaniClean basket strainers have an optional top cover port to accommodate a pressure relief valve, or monitoring gauge.

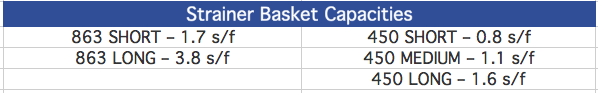

The sanitary basket strainer features SAE 316L stainless steel, as well as exotic alloy construction, and O-ring seals between the strainer basket and the strainer housing. Other features include capacity options from .8 square feet to 3.8 square feet.

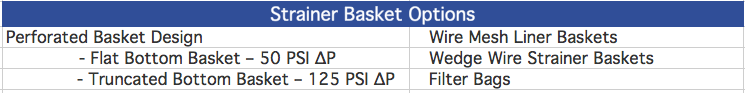

Newark Wire Cloth Sanitary Strainers offer multiple strainer basket options, including:

- Jacketed construction

- Bi-Directional flow

- Perforated baskets

- Flat bottom basket (50 PSI pressure differential)

- Truncated bottom basket (125 PSI pressure differential)

- Wire mesh liner baskets

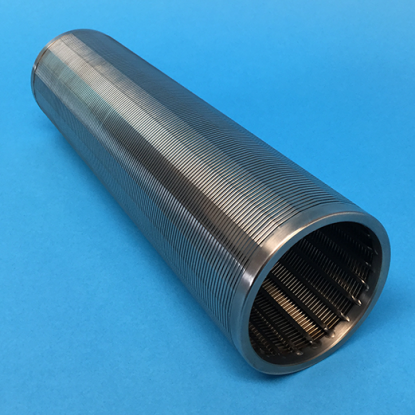

- Wedge wire strainer baskets

- Filter bags